Build Process

Sleeving

We start by double sleeving our cables. Each cable contains a base sleeve applied directly onto the USB cable and a double-sleeve applied on top of the base sleeve. This results in an endless amount of unique color-combos to suit anybody's keyboard setup!

-

Paracord

We use Paracord as our base sleeve. Paracord acts as an excellent first layer, providing a vibrant undertone for your cable.

-

Techflex

Techflex is used as the double-sleeve. The mesh sleeving is applied on top of the Paracord, giving every cable a satisfying feel and premium appearance.

Coiling

Our coiled cables all feature reverse coils. After the first bake and cooling cycle, we reverse the coil direction and bake it again. This makes the coil contract, resulting in a super-snappy, uniformly coiled cable. Check it out yourself!

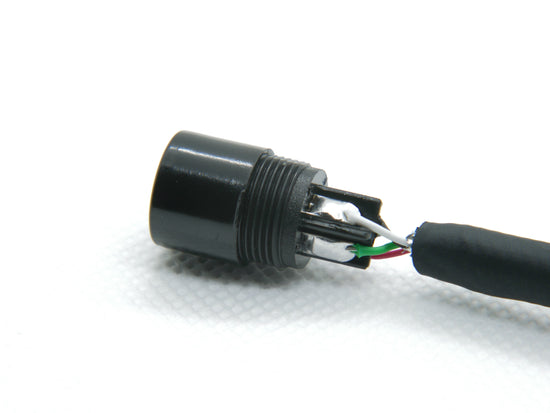

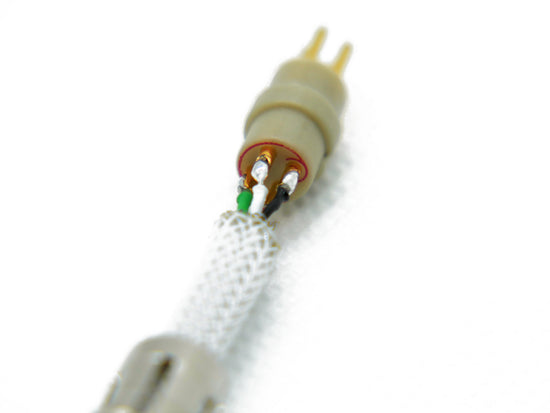

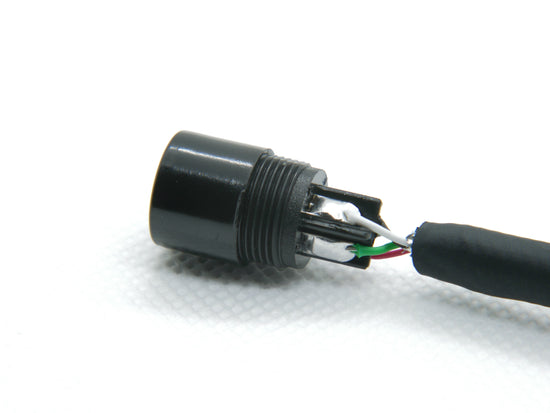

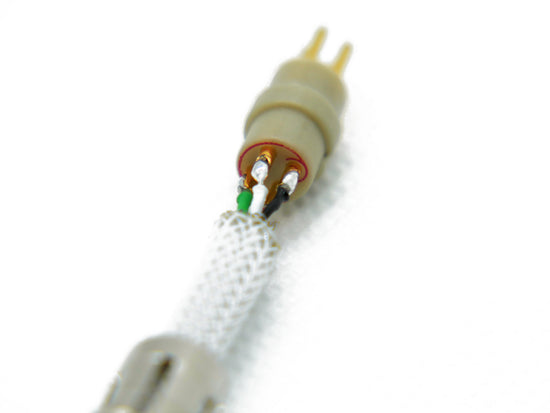

Soldering

Each connector is cleanly soldered, ensuring they'll last the life of the cable. Once completed, each cable is individually tested before shipping out.

-

GX16 Connector

-

Lemo Connector

-

USB Type-A Connector